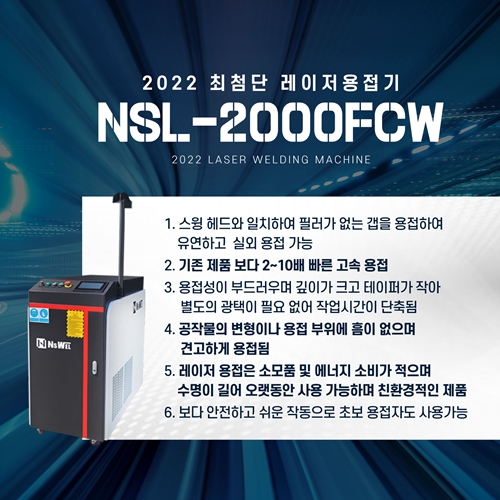

NSL-2000FCW (pictured). NSWEL)

NSWEL has been captivating customers by dealing with items about welders for a long time. The secret is a laser welder, a laser cleaner, and a laser cutter. This is because it records various line-ups such as laser marking machines and laser welding robot solutions. In addition, it is because the difficulties of the work site were solved based on the experience gained from the reference held. In addition, it has the aspect of a global company through active activities not only at home but also abroad.

NSWEL supports everything from manual laser welding machines to laser welding robot automation. (Photo by NSWEL)

NSWEL was established in 1989 and is a laser welder, laser cleaner, and laser cutter. As a company that provided laser marking machines and laser welding boat solutions, it is playing a role as a starting point in the welding machine industry.

It is presenting its own solution based on its systematic response capabilities that are one step ahead of the welder market. By implementing long-term A/S service policies compared to other companies through their know-how, they are responsible for purchasing and follow-up management and build high reliability for customers. It then operates processes such as teaching, installation, and training of equipment that customers need, and supports anyone to easily use welding.

An NSWEL official said, "We provide differentiated services that can maximize the value of the company by meeting various companies over a long period of time. "We will not settle for this and the quality response policy for customers will continue," he said will continue."

Meanwhile, NSWEL is a promising small and medium-sized export company that exports products to Vietnam, Indonesia, Mexico, the United States, Japan, Turkey, Saudi Arabia, Africa Sudan, Russia, Mongolia, China, Malaysia, Singapore, Fiji, and Taiwan. In addition, it participated in various exhibitions at home and abroad for the globalization of NSWEL and continued to carry out promotional strategies to promote its products, enhancing the brand NSWEL.

NSL-2000FCW with technology specific to field environments

The laser welding machine proposed by NSWEL is equipped with technology specialized for the field environment as it is in a welding market with various characteristics and uses of each platform. In particular, the company has proposed the newly upgraded state-of-the-art laser welder NSL-2000FCW to the market.

NSL-2000FCW has the advantage of increasing the efficiency of welding work because it can weld at a high speed 2 to 10 times faster than existing products. Due to its excellent finishing ability, clean results can be expected without additional polishing work, so unnecessary work processes can be reduced without additional work. In addition, perfect quality can be achieved because the welding crop is firmly worked without deformation or defects in the welding area.

This product can also be welded to materials such as stainless steel, copper, aluminum, gold, silver, chromium, titanium, nickel, and other metal alloys, so it can be applied to various industries.

Various styles of welding can be executed by setting the model at the front of the torch. Therefore, up to 10 parameters can be stored, and various laser welding operations can be performed in eight shapes, improving convenience.

An NSWEL official said, "This product, which boasts higher productivity and efficiency than other companies, is already recognized in the market and is so popular that it is applied to signboards, rollforming companies, chemical/stirring and plant companies, semiconductors, auto parts manufacturers, landscaping facilities, and agricultural and industrial facilities."

In addition, the NSCI and NSCS series, which are NSWEL's CO2 welders, can reduce work costs as they generate less slag and are two to three times more efficient than AC arc welding. It has a built-in strong trans, so there is no problem even with high usage rates. Even beginners can express high-efficiency welding technology through simple education, which seems to be good news for companies suffering from recent manpower shortages.