Austrian R&D Center: Driving Innovation in Control Technology

The Austrian R&D Center plays a pivotal role in enhancing the quality and technological capabilities of WOOJIN PLAIMM's injection molding machines. By combining the Austrian team's innovative technologies with the production capabilities of the Korean headquarters, WOOJIN PLAIMM continues to deliver cutting-edge solutions tailored to diverse global demands.

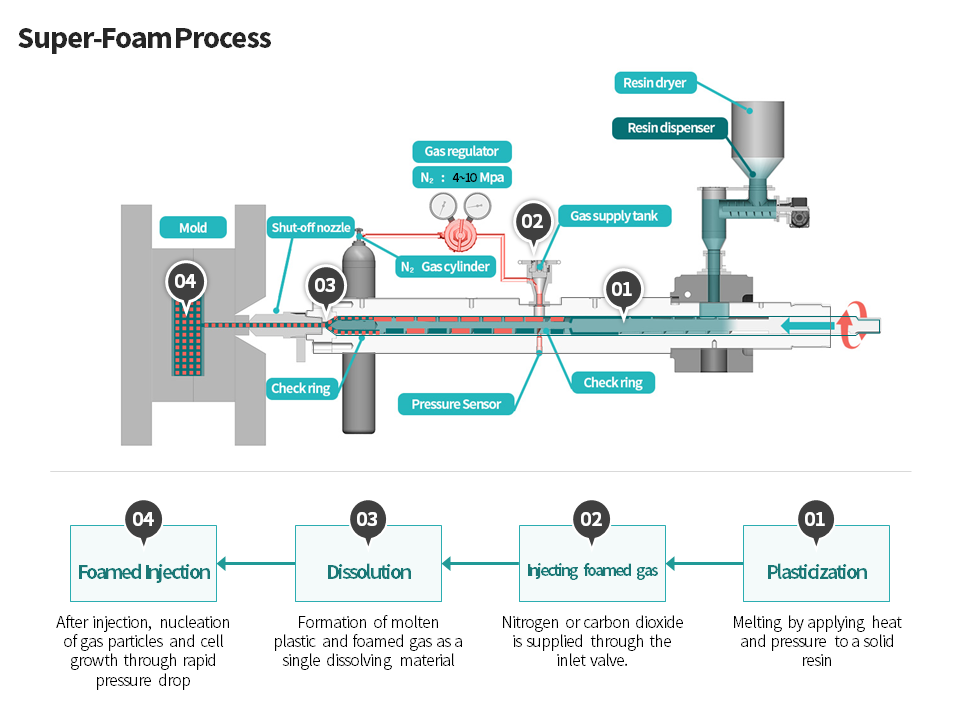

'Super-Foam' Technology: Advancing Efficiency and Sustainability

WOOJIN PLAIMM's 'Super-Foam' technology represents a breakthrough in low-pressure physical micro-foaming injection molding. This technique dissolves inert gas into molten resin under low pressure (below 10 MPa) before injecting it into molds, offering several benefits:

·Weight Reduction: Achieves up to 60% weight reduction compared to solid injection molding.

·Cost Savings: Reduces raw material consumption, lowering production costs.

·Productivity Improvement: Eliminates the need for pressure-holding processes, shortening cycle times.

·Energy Efficiency: Operates at lower processing temperatures, contributing to energy conservation.

·Durability and Versatility: Works with a wide range of materials without requiring specialized foaming resins.

These benefits, coupled with the global push for carbon neutrality, make 'Super-Foam' a transformative solution for industries like automotive, where lightweight and durable components are critical for the growing electric vehicle market.

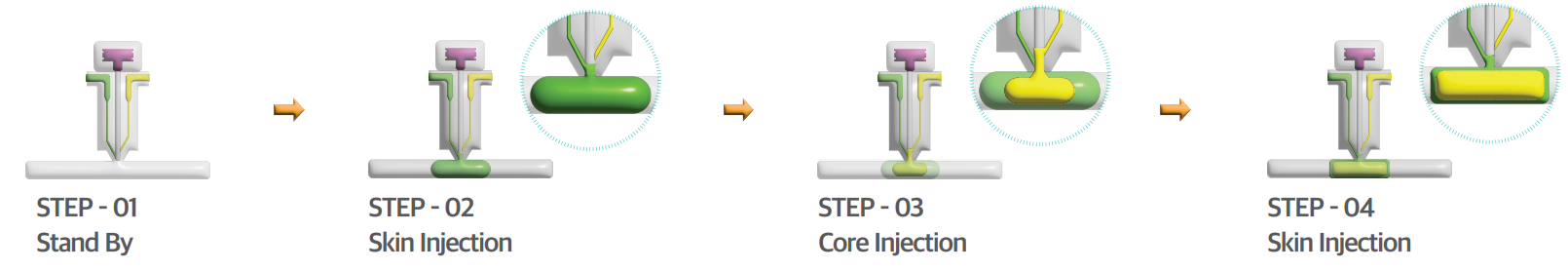

'Clean-Foam' Technology: Beyond Limitations — No Sink, Clean Surface

'Clean-Foam' technology builds upon the innovations of 'Super-Foam,' utilizing a unique molding process where the skin layer is made of virgin material while the core layer consists of either virgin or recycled materials. This approach employs WOOJIN PLAIMM's proprietary foaming techniques, resulting in:

HP : https://woojinplaimm.com

Address : 100, Woojinplaimm-ro, Jangan-myeon, Boeun-gun, Chungbuk-do, Korea

Email : info@wjpim.com